This is an old revision of the document!

In General

2do…

The Components

2do…

How to solder it on the pcb?

“Two legged” SMD components are easy to solder. Place a bit of solder to one of the pads, keep it warm with the iron and place the component to the correct position with the aid of tweezers. Take away the iron when the position is aligned to the pads. Let it cool down for a couple of seconds and solder the other end. Ready !

“Three legged” SMD components are handled the same way. Positioning with one pad and then the two remaining pads.

“Multi legged components” are first positioned correctly on their pads and then diagonally soldered at their corner pins on the pads. This step is very essential for a successful placement. Controlling if all pins are positioned precisely on their corresponding pads is a mandatory to do here. If the positioning is done in the right way the following soldering process is a piece of cake. Down to a spacing of 1.28mm the pin is soldered with a short touch of the soldering iron tip. Ready. If the spacing is smaller this will not work anymore and a sponging technique needs to be used here. Steps for a successful sponging technique ala DF8OE is as follows:

- place a rich amount of RMA-223 flux on all component pins

- cut a handy length of desoldering braid and soak one end with solder

- use this as kind of a “solder paintbrush”. Put a flat, screwdriver shaped tip on the iron and position it 5mm before the end of the soaked desoldering braid. Now use a perpendicular movement towards the pins. Thanks to capillary attraction the pins will be safely connected with their corresponding pads. This will also prevent a bending of single pins cause of the strict perpendicular movement. Step by step finish all the pin lines with that sponging technique movement. Shortings can be removed with clean desoldering braid and cold soldered spots can be removed with a short touch of the soldering iron.

A corresponding video showing this technique can be watched here: [https://youtu.be/6wA8F7sm8VI] This technique can also be handled easily by beginners.

Best practice is always to beginn with the most complicated component the STM32F7 / STM32H7. 99% of the work here is not the soldering, but as mentioned before, the correct positioning of the STM32 with his 144 pads. This needs to be done very precisely to avoid later problems. If the positioning is finished, the following and described before solder process can then be done in 1 to 2 minutes. The two audio codecs (WM 8731) are placed on the pcb and soldered the same way. When finished all three components should be classically cleaned from remaining flux with isopropyl alcohol. All remaining SMD components will then follow on the component side (STM32 side). There is only one single SMD component on the front side. Its recommended to finish one complete item from the list e.g. all 100nF/0603 capacitors, then step to the next item e.g. all 0 Ohm resitors etc. This is only a recommendation and of everybody can follow his own plan here of course.

Soldering is completed with all wired parts (connectors, encoders, USB connectors, male- and female connector strips). In the first step the lithium battery should NOT be soldered onto the pcb. Recommendation for the connector strips is that connectors with electrical voltage and current should be kept female to avoid shortings. So the I40 UI pcb should have the male connector strips on it. Its very useful to keep that rule which makes testing with the RF boards of different owners very easy. If you use a 24LC1025 type serial EEPROM fit R101. For all other EEPROM versions leave it out.

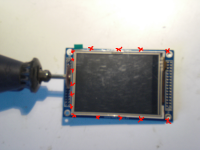

Preparing the 3.2" LCD display

The LCD display needs to be “treated” with a dremel driver or small coping or jig saw first.

The supporting pcb must be cut at the upper, bottom and left side flush to the level of the LCD panel housing itself. The left soldering holes need to be also cut off here. Holes or pins on the right side of the panel, where the flat ribbon cable runs out, need to mandatory kept in place !

On the left side where the soldering holes were cut off, we have the potential danger that copper strips from the pcb can be possibly shorten by the metal frame of the panel. This can easily be avoided with a small piece of scotch tape.

To place the tape lift the panel approximately 0.5mm very carefully with a cutter knife and place the scotch tape under it. Fold it over the pcb edge.

If you do not have an LCD with double line connector strips at the right end, you need to place the connector strips with the long side of the pins from above (!) into the soldering holes. Solder them into place from the bottom side.

This way you do not need to remove the plastic carrier afterwards which may damage the panel connectors.

The short ends of the connector strip pins on the upper (plastic) side need to be cut off to finalize this step.

Special attention need to be payed here to the very sensitive flat ribbon cable to not damage it. A damage of the cable will most likely end up in totaling the LCD.

Attention should also be payed to not use too much solder to avoid little “humps” here. These humps keep the panel connectors from a flat connection to their male counterparts on the UI pcb.

On the left side where the soldering holes were cut off, we have the potential danger that copper strips from the pcb can be possibly shorten by the metal frame of the panel. This can easily be avoided with a small piece of scotch tape.

To place the tape lift the panel approximately 0.5mm very carefully with a cutter knife and place the scotch tape under it. Fold it over the pcb edge.

If you do not have an LCD with double line connector strips at the right end, you need to place the connector strips with the long side of the pins from above (!) into the soldering holes. Solder them into place from the bottom side.

This way you do not need to remove the plastic carrier afterwards which may damage the panel connectors.

The short ends of the connector strip pins on the upper (plastic) side need to be cut off to finalize this step.

Special attention need to be payed here to the very sensitive flat ribbon cable to not damage it. A damage of the cable will most likely end up in totaling the LCD.

Attention should also be payed to not use too much solder to avoid little “humps” here. These humps keep the panel connectors from a flat connection to their male counterparts on the UI pcb.

Detailed photos

Bringing the I40 UHSDR UI pcb to work

The UI pcb can, and of course should be, tested first before connecting it with any RF board. (I40 UI is fully compatible to the original mcHF RF board versions.) The LCD panel should be left off here as well and jumper P6 needs to be bridged. Connect pin 30 of the upper male connector strip with ground and pin 28 with +5V. The actual current should be clearly under 80mA ! If not, supply voltage should be removed immediately and the pcb be checked for possible errors. If all is fine, connect the small USB connector to a PC. Under Windows OS you instantly hear the typical chime for new USB components and the taskbar shows an STM in DFU mode in the information bubble. If you want to check it using Linux you can take a look at kernel messages (tail -f /var/log/messages , possible as “root”) while connecting USB cable. Immediately after connection is done you can see the messages the kernel sends to you. If device is identified you can check dfu capabilities with dfu-util -l .

If all is fine, bootloader and firmware can be flashed with:

Bootloader: dfu-util -d -R -a 0 0483:df11 -D Pfad-zur/bl-40SDR.dfu

Firmware: dfu-util -d -R -a 0 0483:df11 -D Pfad-zur/fw-40SDR.dfu

Windows users do the bootcode and first firmware flashing with the well known “DfuSE Demo” tool from STM. http://www.st.com/en/development-tools/stsw-stm32080.html Its the same way as its done with the originally mcHF UI board.

Actual firmware and bootloader versions for both mcHF and new UHSDR UI can de downloaded here: https://df8oe.github.io/UHSDR/

If this was all successfully completed, then remove the supply voltage and also remove jumper P6. Put the LCD panel into its connectors and reconnect the +5V voltage to pin 28. You should now see the boot process with the UHSDR bootscreen and some error messages. These messages are expected, cause of the missing RF board.